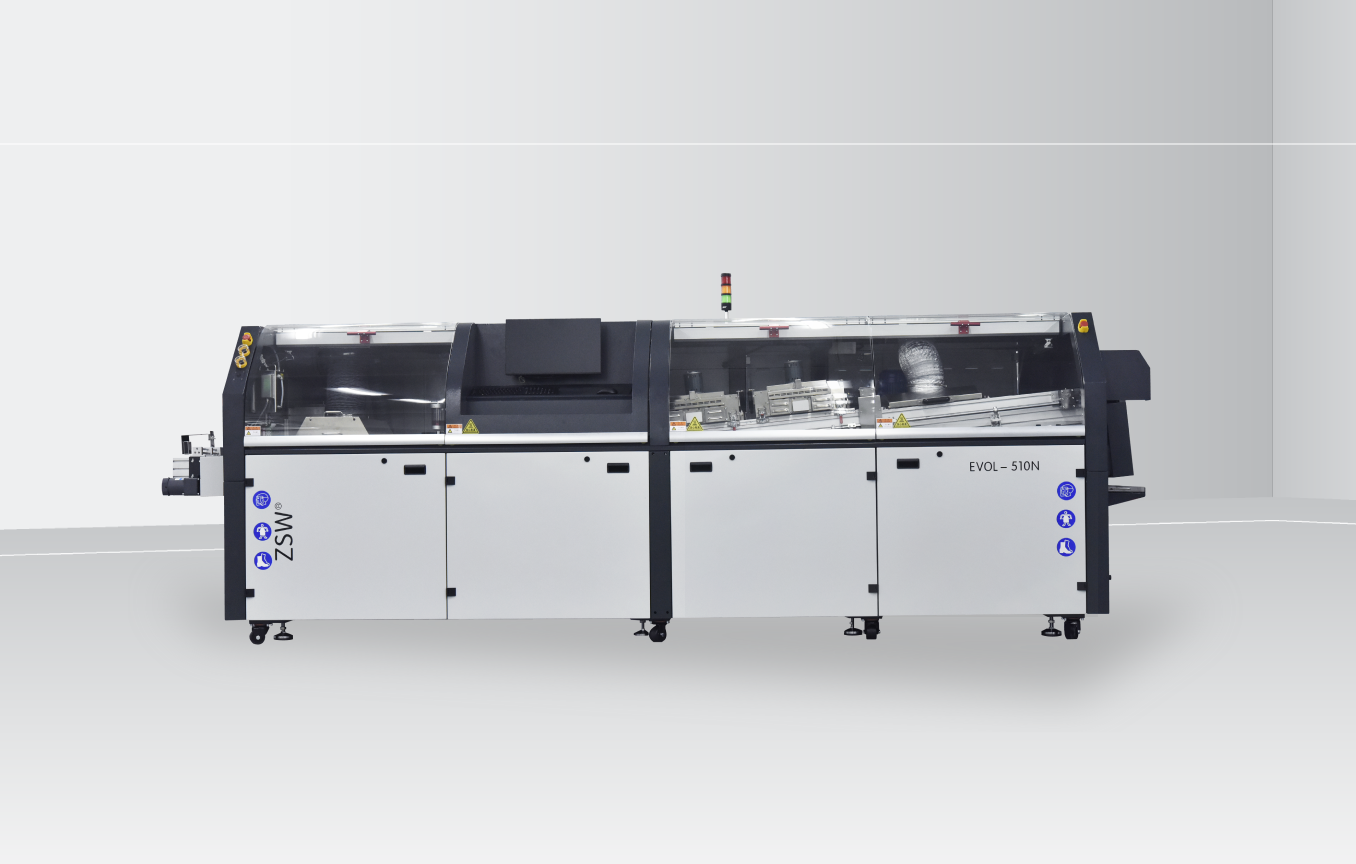

Wave Soldering

EVOL SERIES

EVOLUTIONAL Wave Soldering

Experience the next evolution in wave soldering technology — designed with the unique 3-stages independent conveyor system that effectively separates the fluxing zone, reducing fire hazards while maximizing safety and productivity within minimal floor space.

INDEPENDENT CONVEYOR SYSTEM

Optimum Settings

Fine-tuning the process parameters of each fluxing / preheating / soldering stage without cross-impact on each other for maximum productivity.

Fire Risks Out

Separate conveyors prevents bringing the flux to heat zones, eliminates risk of flux residue build-up in preheating and soldering zones.

Process Stability

With 60% less fingers count in soldering zone, the conveyor system delivers minimal vibration for a stable process, and also less consumable parts.

FEATURES | PERFORMANCES

Selective Flux Spraying

Significantly reduces up to 90% of flux consumption compared to traditional full-spray fluxing and maintain a clean chamber.

Automatic Recipe / Model Switching

Minimal production downtime by automatically adjust the fluxing path & wave height per set values in recipe settings to support mixed production.

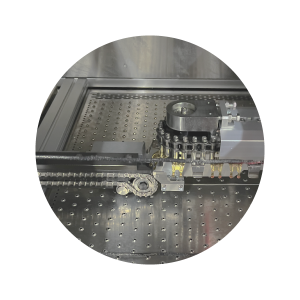

Heavy-Duty Fingers Conveyor

Various V and L fingers combination to convey electronics assemblies and allow larger batches production to improve throughput.

Dual Wave Soldering

With turbulent first wave (chip) to ensure solder fill and reach to compact pins, while laminar second wave (lambda) to complete a clean solder joint.

Ultrasonic Fluxing Ready (Optional)

Upgradable to Sono-Tek ultrasonic nozzles (Z-Select-W) from USA to deliver the finest mist reach for enhanced solder wetting.

Convection Top Preheaters (Optional)

Ensure uniform temperature on both sides of PCB to promote capillary action to fill through holes, giving the top solder joint quality.