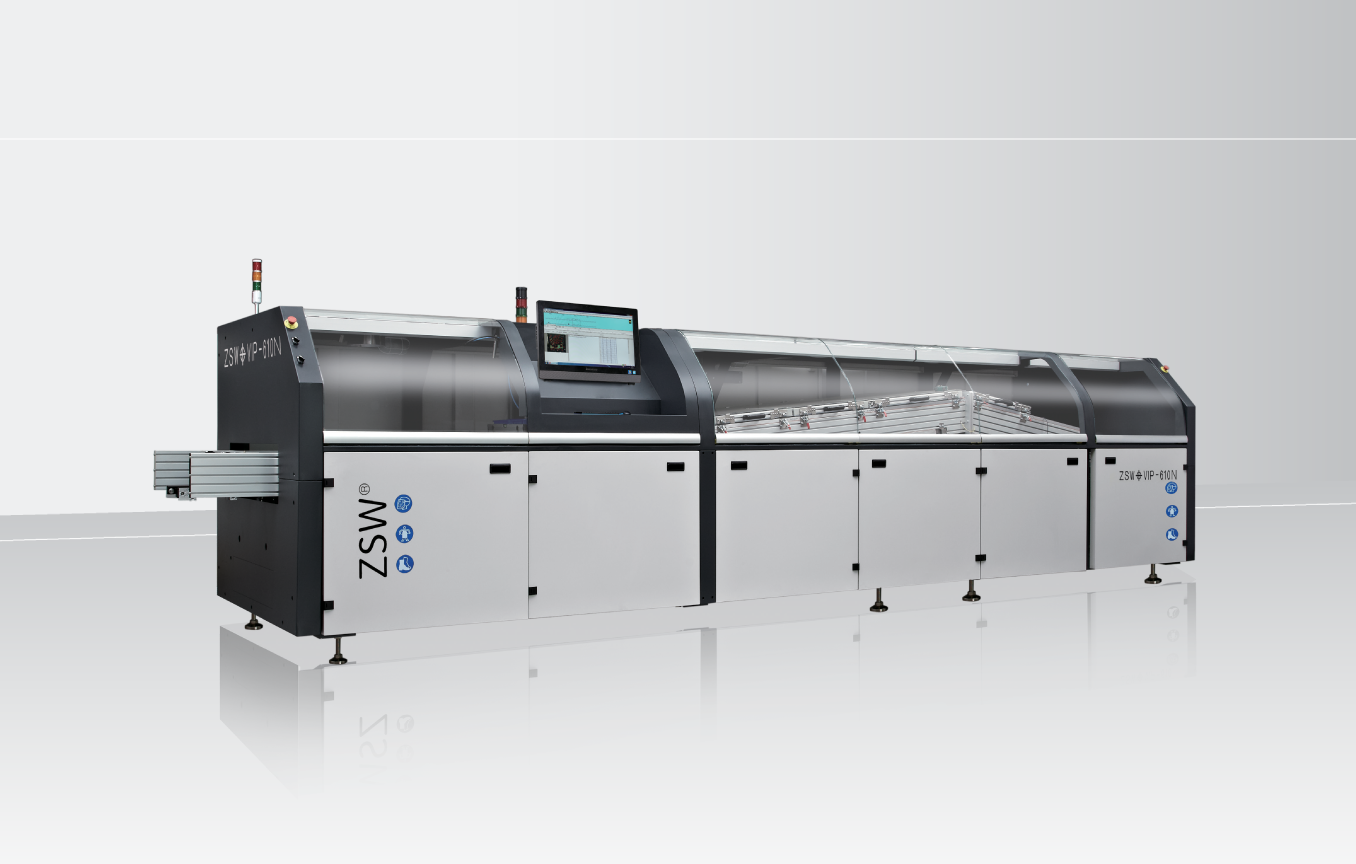

Full-Tunnel Nitrogen Protection Wave Soldering

VIP SERIES

Full-Tunnel Nitrogen Protection Wave Soldering

Experience soldering perfection. Our full-tunnel nitrogen protection technology eliminates any potential oxidation and thermal instability, creating the ideal environment for flawless joints. Every element of the machine is optimized to guarantee precision, consistency, and the best soldering quality in every board.

OUR ADVANTAGES

Fluxing Spray with Metering Pump

Precisely control the flowrate and flux spray pressure with proportional valve to allow minimum flux consumption and a clean fluxing chamber. External fluxer is also available as optional.

Flexible Preheaters Combination

Our flexible preheater combination lets you choose between hot air convection, heating rod, or IR lamp in each zone — giving you full control to create the best temperature balance for your soldering process.

Dual-Wave Soldering System

Combines power and finesse — chip wave drives solder deep into compact pin areas for complete fill, while the lambda wave perfects the finish, leaving a clean and high-quality solder joint.

Solder Level Detection System

Once a low solder level is detected, the system activates an alarm and can automatically replenish solder through an optional auto solder bar feeding system — keeping your production continuous, consistent, and human-error-free.

Ultrasonic Fluxing Ready (Optional)

Enhance your soldering performance with Sono-Tek Z-Select-W ultrasonic nozzle from the USA. Designed for ultra-fine mist delivery, it ensures superior solder wetting and a minimal flux waste.

Nitrogen System Closed-Loop Control (Optional)

Automatically regulates nitrogen levels to create the ideal soldering atmosphere. By maintaining consistent nitrogen purity, it guarantees a brighter solder joints and process repeatability — all while optimizing nitrogen consumption.

FEATURES | PERFORMANCE

Selective Fluxing

Targeted flux application with USA spray nozzle greatly reduces consumption, while ensures a cleaner board and minimum contamination risks.

Smart Exhaust

Features both top and bottom extraction with its inclined hood design, channels the airflow to prevent flux from dripping back onto the PCB.

Controlled Cooling

Integrated cooling within the nitrogen tunnel allows PCBs to cool in the N2 atmosphere to prevent solder joints oxidation.